Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Only top-grade materials are used in our rubber mixing mill machinery, we never cut corners.

Our strict quality control processes guarantee not only a longer product lifespan but also enhanced stability and reliability in performance.

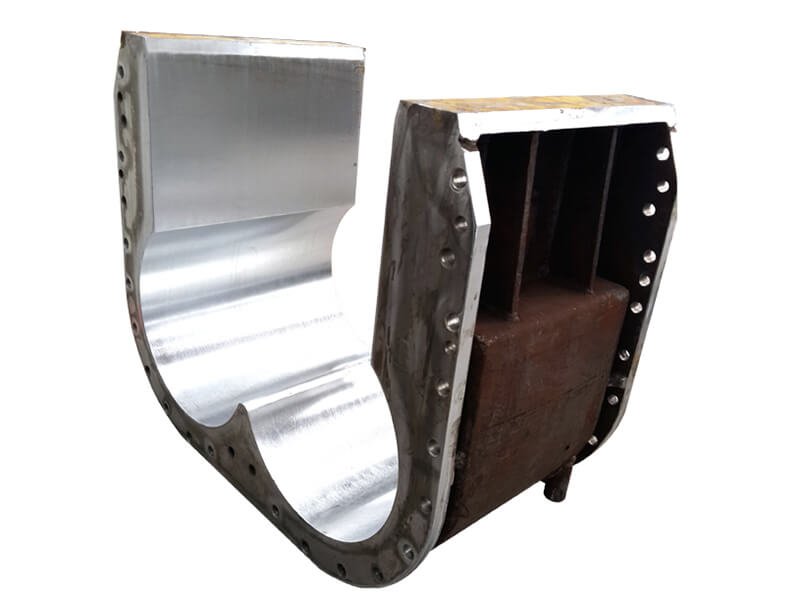

The rotor is two-side shear type,the working edge peaks welded with hard alloy,and the whole working part of the rotor body is plated with hard chromium.

The internal design of the forced cooling or heating channel facilitates temperature control of the rotor.

Our two-roll rubber mixing mill machine features high-quality rolls.

The rolls are made from vanadium titanium metal alloy chilled cast iron, ensuring a hard and wear-resistant surface. The internal cavity is engineered to maintain even temperature distribution on the roll surface.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

| Parameter/model | X(S)N-3 | X(S)N-10×32 | X(S)N-20×32 | X(S)N-35×32 | X(S)N-55×32 | X(S)N-75×32 | X(S)N-95×32 | X(S)N-110×30 | X(S)N-150×30 | X(S)N-200×30 | |

| Total volume | 8 | 25 | 45 | 80 | 125 | 175 | 215 | 250 | 325 | 440 | |

| Working volume | 3 | 10 | 20 | 35 | 55 | 75 | 95 | 110 | 150 | 200 | |

| Motor power | 7.5 | 18.5 | 37 | 55 | 75 | 110 | 132 | 185 | 220 | 280 | |

| Tilting motor power | 0.55 | 1.5 | 1.5 | 2.2 | 2.2 | 4 | 5.5 | 5.5 | 11 | 11 | |

| Tilting angle (°) | 140 | 140 | 140 | 140 | 140 | 140 | 130 | 140 | 140 | 140 | |

| Rotor speed (r/min) | 32/24.5 | 32/25 | 32/26.5 | 32/24.5 | 32/26 | 32/26 | 32/26 | 30/24.5 | 30/24.5 | 30/24.5 | |

| Pressure of compressed air | 0.7-0.9 | 0.6-0.8 | 0.6-0.8 | 0.6-0.8 | 0.6-0.8 | 0.6-0.8 | 0.6-0.8 | 0.6-0.8 | 0.6-0.8 | 0.6-0.8 | |

| Capacity of compressed air (m/min) | ≥0.3 | ≥0.5 | ≥0.7 | ≥0.9 | ≥1.0 | ≥1.3 | ≥1.5 | ≥1.6 | ≥2.0 | ≥2.0 | |

| Pressure of cooling water for rubber (MPa) | 0.2-0.4 | 0.2-0.4 | 0.2-0.4 | 0.3-0.4 | 0.3-0.4 | 0.3-0.4 | 0.3-0.4 | 0.3-0.4 | 0.3-0.4 | 0.3-0.4 | |

| Pressure of steam for plastic (MPa) | 0.5-0.8 | 0.5-0.8 | 0.5-0.8 | 0.5-0.8 | 0.5-0.8 | 0.5-0.8 | 0.5-0.8 | 0.5-0.8 | 0.5-0.8 | 0.5-0.8 | |

| Size (mm) | Length | 1670 | 2380 | 2355 | 3200 | 3360 | 3760 | 3860 | 4075 | 4200 | 4520 |

| Width | 834 | 1353 | 1750 | 1900 | 1950 | 2280 | 2320 | 2712 | 3300 | 3400 | |

| Height | 1850 | 2113 | 2435 | 2950 | 3050 | 3115 | 3320 | 3580 | 3900 | 4215 | |

| Weight (kg) | 1038 | 3000 | 4437 | 6500 | 7850 | 10230 | 11800 | 14200 | 19500 | 22500 | |

We are a professional manufacturer and exporter for rubber machine.

© Qingdao Dahua Machine All Rights Reserved