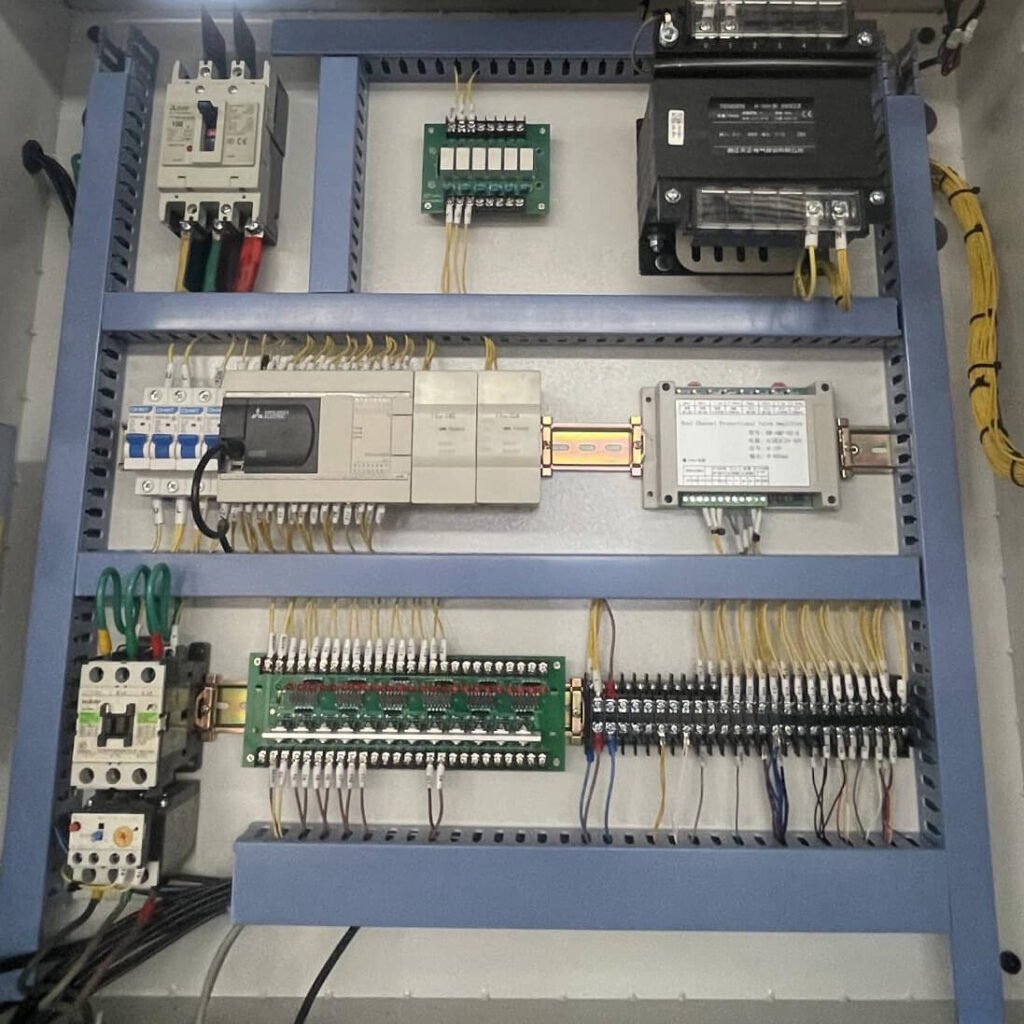

Our electrical control system adopts a PLC and touch screen control method, utilizing world-renowned electrical brands. By integrating expertise from both the electrical and rubber processing fields for software optimization, we have developed a unique rubber production control system where stability and intelligence are our utmost pursuits.

The temperature control system employs solid-state controllers with a precision of ±1°C, significantly ensuring the quality of rubber vulcanization.

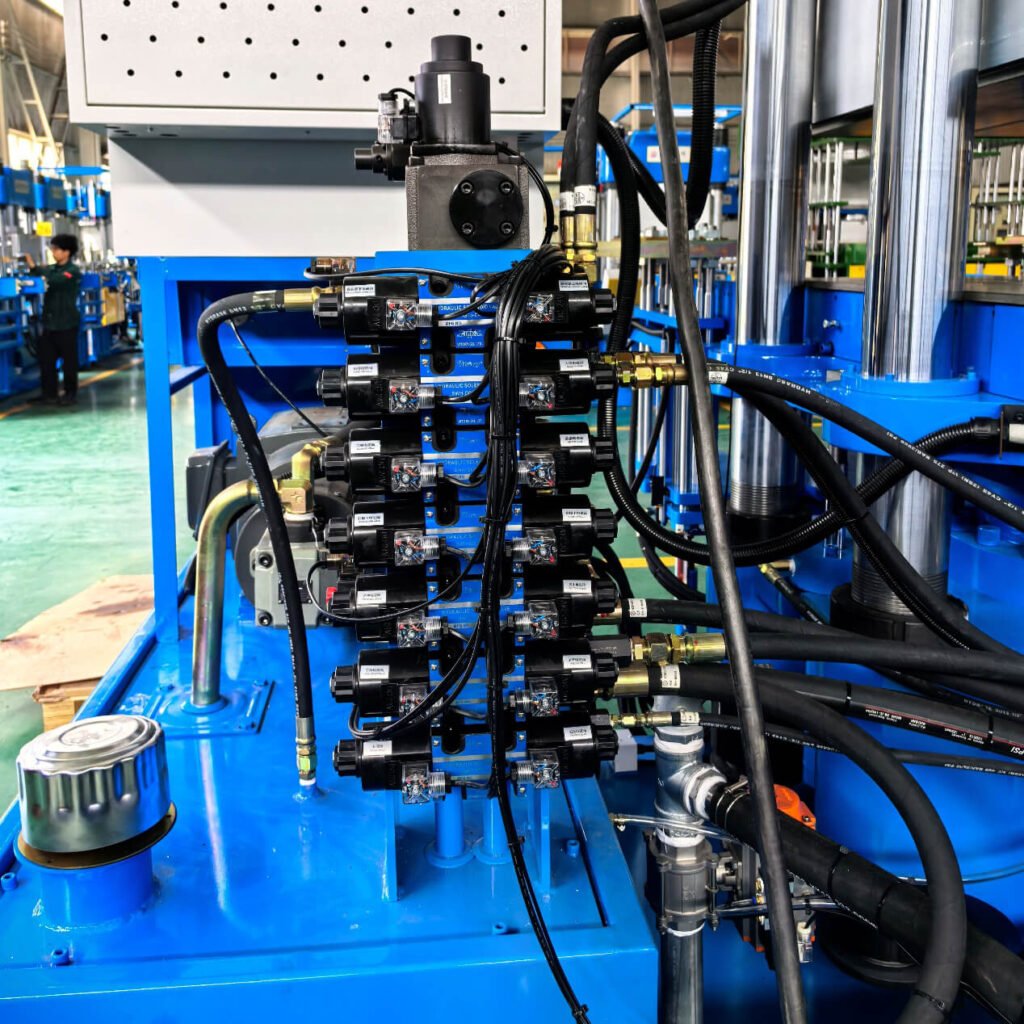

Dynamic Adjustment

Real-time proportional pressure/flow adjustment during stages (mold closing, holding, demolding) ensures optimal curing.

Process Consistency

Uniform mold pressure via proportional valves prevents defects (under-cure/flash). Programmable curves guarantee batch-to-batch precision for automotive/industrial tolerances.

Adaptive Integration

Multi-recipe presets for compound/geometry changes. PLC/HMI compatibility enables centralized monitoring and automation.

Nitrided Hot Plates Enhance Vulcanizing Press Performance

Vacuum Pumps in Vulcanizing Presses: Key Benefits

Eliminate Air Defects: Remove trapped air, moisture, and volatiles during vulcanization to prevent blisters, porosity, and incomplete curing.

Boost Product Integrity: Ensure uniform material density for airtight seals, gaskets, and vibration dampers.

Enhance Process Precision: Achieve defect-free rubber components critical for automotive/industrial applications.

Automated Mold Opening System: Core Advantages

| Model | 200Ton | 250Ton | 300Ton | 350Ton | 400Ton | 500Ton |

| Clamping force(Ton) | 200 | 250 | 300 | 350 | 400 | 500 |

| Stroke(mm) | 250 | 250 | 250 | 300 | 300 | 300 |

| Heating plate size(mm) | up 503x508mm down 554x560mm | up 600x600mm down 600x650mm | up 600x600mm down 650x650mm | up 700x700mm down 750x750mm | up 800x800mm down 850x850mm | up 950x950mm down 1000x1000mm |

| Main cylinder diameter(mm) | 355 | 400 | 450 | 475 | 500 | 560 |

| Horse power(HP) | 10×2 | 10×2 | 10×2 | 15×2 | 15×2 | 15×2 |

| Electrical power(KW) | 22 | 34 | 34 | 43 | 48 | 72 |

| Gross weight(KG) | 90000 | 11500 | 13500 | 16500 | 19500 | 23500 |

| Machine size(L*W*H mm) | 3000x2360x2330 | 3300x2710x2530 | 3450x2630x2600 | 3600x2950x2600 | 3800x3300x2800 | 4200x3600x3300 |

We are a professional manufacturer and exporter for rubber machine.

© Qingdao Dahua Machine All Rights Reserved